→ Nickel Alloys

→ PRODUCTS

We are industrial suppliers of Nickel Alloy 200 Products |

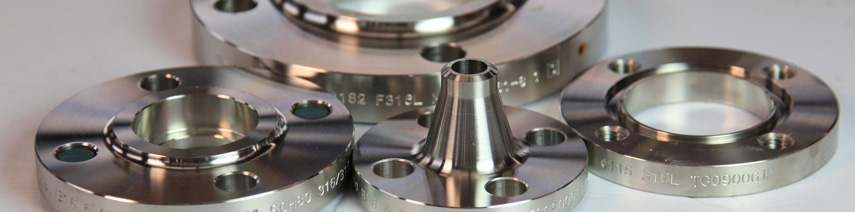

Home / Products / Nickel Alloys / Incoloy 330 / ASTM B366 Incoloy 330 Nipoflange INCOLOY alloy 330 (UNS N08330/W. Nr. 1.4886)A nickel-iron-chromium alloy with an addition of silicon for enhanced oxidation resistance. It has good strength at high temperatures and excellent resistance to carburizing and oxidizing atmospheres. The alloy’s austenitic microstructure remains stable during long-time exposure to high temperature. Used in industrial heating for furnace muffles, retorts, and conveyor systems and for heat-treating baskets and fixtures.

ASTM B366 Incoloy 330 NipoflangeSpecifications

ASTM B366 Incoloy 330 Nipoflange Inventory Stock at factory rate:-

DimensionsIncoloy 330 Chemical composition:

Machining:Machining of INCOLOY alloy 330 requires more power than similar operations on mild steel and should be performed by techniques that minimize work hardening. Welding:INCOLOY alloy 330 is weldable by conventional processes.Shielded-metal-arc welding should be done with INCO-Co-WELD A welding electrode; gas-shielded-arc welding with INCONEL filler metal 82. Acceptable welds have been made in relatively heavy sections with these welding products. For additional strength and corrosion resistance up to 2100°F (1150°C), INCONEL filler metal 617 and INCONEL welding electrode 117 may be used. Fabrication:INCOLOY alloy 330 is readily hot- or cold-formed using standard procedures for stainless steels and nickel alloys. The range for hot forming is 1750 to 2100°F (954 to 1149°C).

Main Export Market

|

||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||