→ PRODUCTS

ISO 9001:2008 Certified

We are regular suppliers from China for DIN FLANGE PN6-PN40

|

|

Highly acclaimed Manufacturer & Exporter presents best offer ever on DIN FLANGE PN6-PN40

Home / Products / Flanges / DIN FLANGE PN6-PN40

DIN FLANGE PN6-PN40

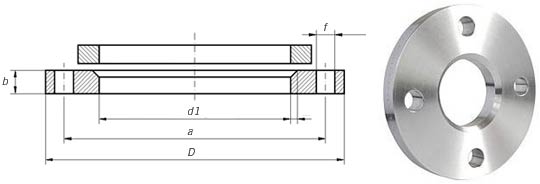

Dimensions

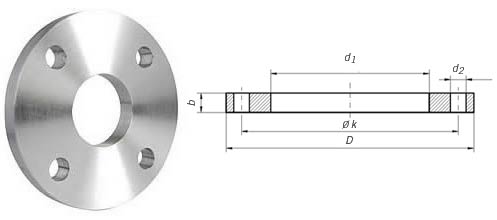

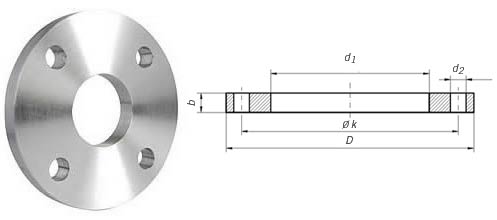

Plate Flange

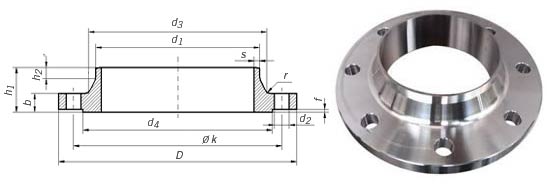

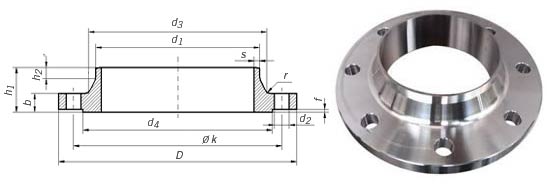

Welding Neck Flange

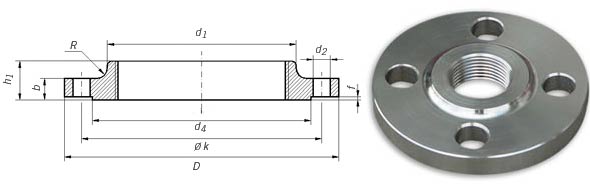

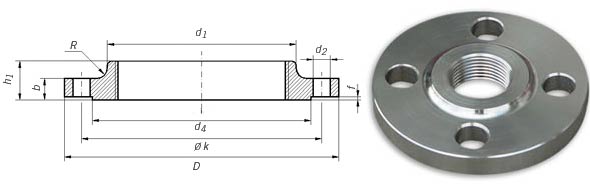

Threaded Flange

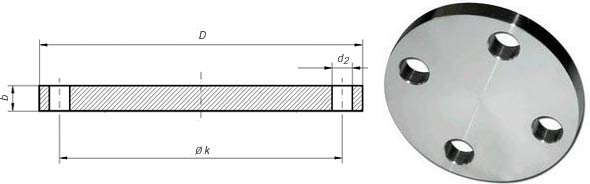

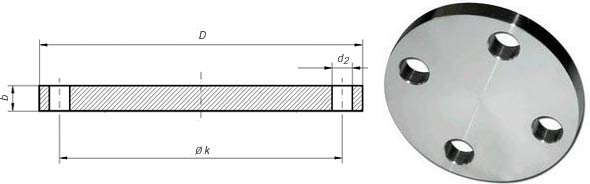

Blind Flange

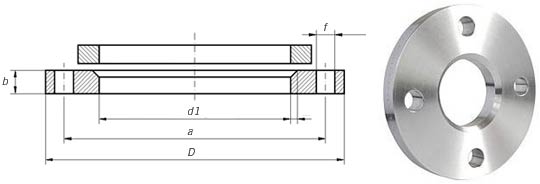

Lapped/Loose Flange

Dimensions & Approximate Masses of DIN 2573 PN6 Flange

Germany standard flange DIN 2573 for soldering or welding Nominall Pressure 6 |

Flansche, glatt zum löten oder schweißen DIN 2573 Nenndruck 6 |

Brides plates a souder DIN 2573 pression nominale 6 |

| Pipe |

Flange |

Screws |

Weight

(7,85 Kg/dm3) |

Rated

Diameter |

d1 |

d5 |

D |

b |

c |

k |

Holes |

Thread |

d2 |

Kg |

| ISO Series 1 |

DIN Series 2 |

| 15 |

- |

20 |

21 |

80 |

12 |

5 |

55 |

4 |

M 10 |

11 |

0,41 |

| 21,3 |

- |

22 |

| 20 |

- |

25 |

26 |

90 |

14 |

5 |

65 |

4 |

M 10 |

11 |

0,60 |

| 26,9 |

- |

27,6 |

| 25 |

- |

30 |

31 |

100 |

14 |

5 |

75 |

4 |

M 10 |

11 |

0,74 |

| 33,7 |

- |

34,4 |

| 32 |

- |

38 |

39 |

120 |

16 |

5 |

90 |

4 |

M 12 |

14 |

1,19 |

| 42,4 |

- |

43,1 |

| 40 |

- |

44,5 |

45,5 |

130 |

16 |

5 |

100 |

4 |

M 12 |

14 |

1,39 |

| 48,3 |

- |

49 |

| 50 |

- |

57 |

58,1 |

140 |

16 |

6 |

110 |

4 |

M 12 |

14 |

1,53 |

| 60,3 |

- |

61,1 |

| 65 |

76,1 |

- |

77,1 |

160 |

16 |

6 |

130 |

4 |

M 12 |

14 |

1,89 |

| 80 |

88,9 |

- |

90,3 |

190 |

18 |

7 |

150 |

4 |

M 16 |

18 |

2,98 |

| 100 |

- |

108 |

109,6 |

210 |

18 |

7 |

170 |

4 |

M 16 |

18 |

3,46 |

| 114,3 |

- |

115,9 |

| 125 |

- |

133 |

134,8 |

240 |

20 |

7 |

200 |

8 |

M 16 |

18 |

4,60 |

| 139,7 |

- |

141,6 |

| 150 |

- |

159 |

161,1 |

265 |

20 |

7 |

225 |

8 |

M 16 |

18 |

5,22 |

| 168,3 |

- |

170,5 |

| 200 |

219,1 |

- |

221,8 |

320 |

22 |

7 |

280 |

8 |

M 16 |

18 |

7,15 |

| 250 |

- |

267 |

270,2 |

375 |

24 |

7 |

335 |

12 |

M 16 |

18 |

9,61 |

| 273 |

- |

276,2 |

| 300 |

323,9 |

- |

327,6 |

440 |

24 |

7 |

395 |

12 |

M 20 |

22 |

12,60 |

| 350 |

355,6 |

- |

359,7 |

490 |

26 |

7 |

445 |

12 |

M 20 |

22 |

15,60 |

| - |

368 |

372,2 |

| 400 |

406,4 |

- |

411 |

540 |

28 |

7 |

495 |

16 |

M 20 |

22 |

18,40 |

| - |

419 |

423,7 |

| (450)* |

457 |

- |

462,5 |

595 |

30 |

7 |

550 |

16 |

M 20 |

22 |

21,40 |

| 500 |

508 |

- |

531,6 |

645 |

30 |

7 |

600 |

20 |

M 20 |

22 |

24,60 |

NOTE:

1. Facing according to DIN 2526

Flat face:

Form A, Face without any requirements

Form B, Face Rz=160, machined (not smoother than 40µm)

Raised Face:

Form C, Face Rz=160, machined (not smoother than 40µm)

Form D, Face Rz=40, machined

Form E, Face Rz=16, machined

2. Tongue and groove according to DIN 2512

Form F, Tongue

Form N, Groove

3. Male and Female according to DIN 2513, DIN 2514

Form V13, V14, Male

Form R13, R16, Female

4. Chemfering for diaphragm-weld packings, PN64-PN400, according to DIN 2695

5. Facing for lens-shaped joints, PN64-PN400, according to DIN 2696

DIN 2631 PN6 WELDING NECK FLANGE RF

Dimensions & Approx Masses of DIN 2631 PN6 WNRF Flange

Germany standard flange DIN 2631 welding neck flanges; nominal pressure 6 |

Vorschweißflansche DIN 2631 Nenndruck 6 |

Brides à souder à collerette DIN 2631: pression nominale 6 |

| Pipe |

Flange |

Neck |

Raised face |

Screws |

Weight |

| (7,85 Kg/dm3) |

| Rated |

d1 |

D |

b |

k |

h1 |

d3 |

s |

r |

h2 |

d4 |

f |

Holes |

Thread |

d2 |

Kg |

| Diameter |

ISO Series |

DIN Series |

| 15 |

- |

20 |

80 |

12 |

55 |

30 |

28 |

2 |

4 |

6 |

40 |

2 |

4 |

M 10 |

11 |

0,392 |

| 21,3 |

- |

30 |

| 20 |

- |

25 |

90 |

14 |

65 |

32 |

35 |

2,3 |

4 |

6 |

50 |

2 |

4 |

M 10 |

11 |

0,592 |

| 26,9 |

- |

38 |

| 25 |

- |

30 |

100 |

14 |

75 |

35 |

40 |

2,6 |

4 |

6 |

60 |

2 |

4 |

M 10 |

11 |

0,747 |

| 33,7 |

- |

42 |

| 32 |

- |

38 |

120 |

14 |

90 |

35 |

50 |

2,6 |

6 |

6 |

70 |

2 |

4 |

M 12 |

14 |

1,05 |

| 42,4 |

- |

55 |

| 40 |

- |

44,5 |

130 |

14 |

100 |

38 |

58 |

2,6 |

6 |

7 |

80 |

3 |

4 |

M 12 |

14 |

1,18 |

| 48,3 |

- |

62 |

| 50 |

- |

57 |

140 |

14 |

110 |

38 |

70 |

2,9 |

6 |

8 |

90 |

3 |

4 |

M 12 |

14 |

1,34 |

| 60,3 |

- |

74 |

| 65 |

76,1 |

- |

160 |

14 |

130 |

38 |

88 |

2,9 |

6 |

9 |

110 |

3 |

4 |

M 12 |

14 |

1,67 |

| 80 |

88,9 |

- |

190 |

16 |

150 |

42 |

102 |

3,2 |

8 |

10 |

128 |

3 |

4 |

M 16 |

18 |

2,71 |

| 100 |

- |

108 |

210 |

16 |

170 |

45 |

122 |

3,6 |

8 |

10 |

148 |

3 |

4 |

M 16 |

18 |

3,24 |

| 114,3 |

|

130 |

| 125 |

- |

133 |

240 |

18 |

200 |

48 |

148 |

4 |

8 |

10 |

178 |

3 |

8 |

M 16 |

18 |

4,49 |

| 139,7 |

- |

155 |

| 150 |

- |

159 |

265 |

18 |

225 |

48 |

172 |

4,5 |

10 |

12 |

202 |

3 |

8 |

M 16 |

18 |

5,15 |

| 168,3 |

- |

184 |

| 200 |

219,1 |

- |

320 |

20 |

280 |

55 |

236 |

5,9 |

10 |

15 |

258 |

3 |

8 |

M 16 |

18 |

7,78 |

| 250 |

- |

267 |

375 |

22 |

335 |

60 |

282 |

6,3 |

12 |

15 |

312 |

3 |

12 |

M 16 |

18 |

10,8 |

| 273 |

- |

290 |

| 300 |

323,9 |

- |

440 |

22 |

395 |

62 |

342 |

7,1 |

15 |

15 |

365 |

4 |

12 |

M 20 |

22 |

14 |

| 350 |

355,6 |

- |

490 |

22 |

445 |

62 |

385 |

7,1 |

12 |

15 |

415 |

4 |

12 |

M 20 |

22 |

18,5 |

| - |

368 |

16,7 |

| 400 |

406,4 |

- |

540 |

22 |

495 |

65 |

438 |

7,1 |

12 |

15 |

465 |

4 |

16 |

M 20 |

22 |

21,2 |

| - |

419 |

19 |

| 500 |

508 |

- |

645 |

24 |

600 |

68 |

538 |

7,1 |

12 |

15 |

570 |

4 |

20 |

M 20 |

22 |

28,6 |

| 600 |

610 |

- |

755 |

24 |

705 |

70 |

640 |

7,1 |

12 |

16 |

670 |

5 |

20 |

M 24 |

26 |

31,5 |

| 700 |

711 |

- |

860 |

24 |

810 |

70 |

740 |

7,1 |

12 |

16 |

775 |

5 |

24 |

M 24 |

26 |

37,4 |

| 800 |

813 |

- |

975 |

24 |

920 |

70 |

842 |

7,1 |

12 |

16 |

880 |

5 |

24 |

M 27 |

30 |

46,1 |

| 900 |

914 |

- |

1075 |

26 |

1020 |

70 |

942 |

7,1 |

12 |

16 |

980 |

5 |

24 |

M 27 |

30 |

55,6 |

| 1000 |

1016 |

- |

1175 |

26 |

1120 |

70 |

1045 |

7,1 |

16 |

16 |

1080 |

5 |

28 |

M 27 |

30 |

61,9 |

NOTE:

1. Facing according to DIN 2526

Flat face:

Form A, Face without any requirements

Form B, Face Rz=160, machined (not smoother than 40µm)

Raised Face:

Form C, Face Rz=160, machined (not smoother than 40µm)

Form D, Face Rz=40, machined

Form E, Face Rz=16, machined

2. Tongue and groove according to DIN 2512

Form F, Tongue

Form N, Groove

3. Male and Female according to DIN 2513, DIN 2514

Form V13, V14, Male

Form R13, R16, Female

4. Chemfering for diaphragm-weld packings, PN64-PN400, according to DIN 2695

5. Facing for lens-shaped joints, PN64-PN400, according to DIN 2696

DIN 2565 PN6/DIN 2566 PN16 THREADED FLANGE

Dimensions & Masses of DIN 2565/DIN 2566 Threaded Flange

| DIN 2565 PN 6 THREADED FLANGE SPECIFICATION |

Rated

Diameter |

|

Flange |

Neck |

Raised face |

Screws |

Weight

(7,85 Kg/dm3) |

| d1 |

Thread |

D |

b |

k |

h1 |

d3 |

d4 |

f |

Holes |

Thread |

d2 |

Kg |

| 15 |

21,3 |

R 1/2 |

80 |

12 |

55 |

20 |

30 |

40 |

2 |

4 |

M 10 |

11 |

0,373 |

| 20 |

26,9 |

R 3/4 |

90 |

14 |

65 |

24 |

40 |

50 |

2 |

4 |

M 10 |

11 |

0,59 |

| 25 |

33,7 |

R 1 |

100 |

14 |

75 |

24 |

50 |

60 |

2 |

4 |

M 10 |

11 |

0,743 |

| 32 |

42,4 |

R 1 1/4 |

120 |

14 |

90 |

26 |

60 |

70 |

2 |

4 |

M 12 |

14 |

1,05 |

| 40 |

48,3 |

R 1 1/2 |

130 |

14 |

100 |

26 |

70 |

80 |

3 |

4 |

M 12 |

14 |

1,2 |

| 50 |

60,3 |

R 2 |

140 |

14 |

110 |

28 |

80 |

90 |

3 |

4 |

M 12 |

14 |

1,37 |

| 65 |

76,1 |

R 2 1/2 |

160 |

14 |

130 |

32 |

100 |

110 |

3 |

4 |

M 12 |

14 |

1,92 |

| 80 |

88,9 |

R 3 |

190 |

16 |

150 |

34 |

110 |

128 |

3 |

4 |

M 16 |

18 |

2,82 |

| 100 |

114,3 |

R 4 |

210 |

16 |

170 |

38 |

130 |

148 |

3 |

4 |

M 16 |

18 |

3,19 |

| 125 |

139,7 |

R 5 |

240 |

18 |

200 |

40 |

160 |

178 |

3 |

8 |

M 16 |

18 |

4,47 |

| 150 |

165,1 |

R 6 |

265 |

18 |

225 |

44 |

185 |

202 |

3 |

8 |

M 16 |

18 |

5,3 |

| DIN 2566 PN16 THREADED FLANGE SPECIFICATION |

Rated

Diameter |

|

Flange |

Neck |

Raised face |

Screws |

Weight

(7,85 Kg/dm3) |

| d1 |

Thread |

D |

b |

k |

h1 |

d3 |

d4 |

f |

Holes |

Thread |

d2 |

Kg |

| 15 |

21,3 |

R 1/2 |

95 |

14 |

65 |

20 |

35 |

45 |

2 |

4 |

M 12 |

14 |

0,613 |

| 20 |

26,9 |

R 3/4 |

105 |

16 |

75 |

24 |

45 |

58 |

2 |

4 |

M 12 |

14 |

0,91 |

| 25 |

33,7 |

R 1 |

115 |

16 |

85 |

24 |

52 |

68 |

2 |

4 |

M 12 |

14 |

1,1 |

| 32 |

42,4 |

R 1 1/4 |

140 |

16 |

100 |

26 |

60 |

78 |

2 |

4 |

M 16 |

18 |

1,6 |

| 40 |

48,3 |

R 1 1/2 |

150 |

16 |

110 |

26 |

70 |

88 |

3 |

4 |

M 16 |

18 |

1,78 |

| 50 |

60,3 |

R 2 |

165 |

18 |

125 |

28 |

85 |

102 |

3 |

4 |

M 16 |

18 |

2,43 |

| 65 |

76,1 |

R 2 1/2 |

185 |

18 |

145 |

32 |

105 |

122 |

3 |

4 |

M 16 |

18 |

3,18 |

| 80 |

88,9 |

R 3 |

200 |

20 |

160 |

34 |

118 |

138 |

3 |

8 |

M 16 |

18 |

4,12 |

| 100 |

114,3 |

R 4 |

220 |

20 |

180 |

38 |

140 |

158 |

3 |

8 |

M 16 |

18 |

4,47 |

| 125 |

139,7 |

R 5 |

250 |

22 |

210 |

40 |

168 |

188 |

3 |

8 |

M 16 |

18 |

6,13 |

| 150 |

165,1 |

R 6 |

285 |

22 |

240 |

44 |

195 |

212 |

3 |

8 |

M 20 |

22 |

7,92 |

NOTE:

1. Facing according to DIN 2526

Flat face:

Form A, Face without any requirements

Form B, Face Rz=160, machined (not smoother than 40µm)

Raised Face:

Form C, Face Rz=160, machined (not smoother than 40µm)

Form D, Face Rz=40, machined

Form E, Face Rz=16, machined

2. Tongue and groove according to DIN 2512

Form F, Tongue

Form N, Groove

3. Male and Female according to DIN 2513, DIN 2514

Form V13, V14, Male

Form R13, R16, Female

4. Chemfering for diaphragm-weld packings, PN64-PN400, according to DIN 2695

5. Facing for lens-shaped joints, PN64-PN400, according to DIN 2696

DIN 2527 BLIND FLANGE PN6, PN10, PN16, PN25, PN40

Dimensions & Approximate Masses of DIN 2527 Blind Flange

Germany standard flange DIN 2527 Blind flange Nominal Pressure 6 to 100 |

Blindflansche Nenndruck 6 bis 100 |

Brides plaines, pressions nominales 6 à 100 |

| DIN 2527 PN6 BLIND FLANGE |

Rated

Diameter |

Flange |

Screws |

Weight

(7,85 Kg/dm3) |

| D |

b |

k |

Number |

Thread |

d2 |

Shape B |

| Kg |

| 15 |

80 |

12 |

55 |

4 |

M 10 |

11 |

0.44 |

| 20 |

90 |

14 |

65 |

0.66 |

| 25 |

100 |

14 |

75 |

0.83 |

| 32 |

120 |

14 |

90 |

M 12 |

14 |

1.18 |

| 40 |

130 |

14 |

100 |

1.39 |

| 50 |

140 |

14 |

110 |

1.63 |

| 65 |

160 |

14 |

130 |

2.15 |

| 80 |

190 |

16 |

150 |

M 16 |

18 |

3.44 |

| 100 |

210 |

16 |

170 |

4.22 |

| 125 |

240 |

18 |

200 |

8 |

6.11 |

| 150 |

265 |

18 |

225 |

7.51 |

| 200 |

320 |

20 |

280 |

12.31 |

| 250 |

375 |

22 |

335 |

12 |

18.54 |

| 300 |

440 |

22 |

395 |

M 20 |

22 |

25.46 |

| 350 |

490 |

22 |

445 |

31.77 |

| 400 |

540 |

22 |

495 |

16 |

38.49 |

| 500 |

645 |

24 |

600 |

20 |

60.10 |

| DIN 2527 PN10 BLIND FLANGE |

Rated

Diameter |

Flange |

Screws |

Weight

(7,85 Kg/dm3) |

| D |

b |

k |

Number |

Thread |

d2 |

Shape B |

| Kg |

| 15 |

95 |

14 |

65 |

4 |

M 12 |

14 |

0,72 |

| 20 |

105 |

16 |

75 |

1,01 |

| 25 |

115 |

16 |

85 |

1,23 |

| 32 |

140 |

16 |

100 |

M 16 |

18 |

1,8 |

| 40 |

150 |

16 |

110 |

2,09 |

| 50 |

165 |

18 |

125 |

2,88 |

| 65 |

185 |

18 |

145 |

3,66 |

| 80 |

200 |

20 |

160 |

4,77 |

| 100 |

220 |

20 |

180 |

8 |

5,65 |

| 125 |

250 |

22 |

210 |

8,42 |

| 150 |

285 |

22 |

240 |

M 20 |

22 |

10,4 |

| 200 |

340 |

24 |

295 |

16,5 |

| 250 |

395 |

26 |

350 |

12 |

24 |

| 300 |

445 |

26 |

400 |

30,9 |

| 350 |

505 |

26 |

460 |

16 |

40,6 |

| 400 |

565 |

26 |

515 |

M 24 |

26 |

49,4 |

| 500 |

670 |

28 |

620 |

20 |

75 |

| DIN 2527 PN16 BLIND FLANGE |

Rated

Diameter |

Flange |

Screws |

Weight

(7,85 Kg/dm3) |

| D |

b |

k |

Number |

Thread |

d2 |

Shape B |

| Kg |

| 15 |

95 |

14 |

65 |

4 |

M 12 |

14 |

0,72 |

| 20 |

105 |

16 |

75 |

1,01 |

| 25 |

115 |

16 |

85 |

1,23 |

| 32 |

140 |

16 |

100 |

M 16 |

18 |

1,8 |

| 40 |

150 |

16 |

110 |

2,09 |

| 50 |

165 |

18 |

125 |

2,88 |

| 65 |

185 |

18 |

145 |

3,66 |

| 80 |

200 |

20 |

160 |

8 |

4,77 |

| 100 |

220 |

20 |

180 |

5,65 |

| 125 |

250 |

22 |

210 |

8,42 |

| 150 |

285 |

22 |

240 |

M 20 |

22 |

10,4 |

| 200 |

340 |

24 |

295 |

12 |

16,1 |

| 250 |

405 |

26 |

355 |

M 24 |

26 |

24,9 |

| 300 |

460 |

28 |

410 |

35,1 |

| 350 |

520 |

30 |

470 |

16 |

47,8 |

| 400 |

580 |

32 |

525 |

M 27 |

30 |

63,5 |

| 500 |

715 |

36 |

650 |

20 |

M 30 |

33 |

102 |

NOTE:

1. Facing according to DIN 2526

Flat face:

Form A, Face without any requirements

Form B, Face Rz=160, machined (not smoother than 40µm)

Raised Face:

Form C, Face Rz=160, machined (not smoother than 40µm)

Form D, Face Rz=40, machined

Form E, Face Rz=16, machined

2. Tongue and groove according to DIN 2512

Form F, Tongue

Form N, Groove

3. Male and Female according to DIN 2513, DIN 2514

Form V13, V14, Male

Form R13, R16, Female

4. Chemfering for diaphragm-weld packings, PN64-PN400, according to DIN 2695

5. Facing for lens-shaped joints, PN64-PN400, according to DIN 2696

DIN 2642 PN10 LOOSE FLANGE

Dimensions & Approximate Masses of DIN 2642 PN10 Flange

Germany standard flange DIN 2642 lapped flange; nominal pressure 10 |

|

Lose Flansche Vorschweißbördel Glatte Bunde DIN 2642 Nenndruck 10 |

Brides tournantes: pression nominale 10 |

| Pipe |

Flange |

Screws |

Weight

(7,85 Kg/dm3) |

Rated

Diameter |

d1 |

D |

d6 |

b |

k |

e |

Holes |

Thread |

d2 |

Kg |

ISO

Series 1 |

DIN

Series 2 |

| 15 |

- |

20 |

95 |

22 |

14 |

65 |

3 |

4 |

M 12 |

14 |

0,689 |

| 21,3 |

- |

24 |

| 20 |

- |

25 |

105 |

28 |

14 |

75 |

3 |

4 |

M 12 |

14 |

0,806 |

| 26,9 |

- |

30 |

| 25 |

- |

30 |

115 |

33 |

16 |

85 |

4 |

4 |

M 12 |

14 |

1,11 |

| 33,7 |

- |

36 |

| 32 |

- |

38 |

140 |

42 |

16 |

100 |

4 |

4 |

M 16 |

18 |

1,64 |

| 42,4 |

- |

46 |

| 40 |

- |

44,5 |

150 |

50 |

16 |

110 |

4 |

4 |

M 16 |

18 |

1,86 |

| 48,3 |

- |

54 |

| 50 |

- |

57 |

165 |

62 |

16 |

125 |

5 |

4 |

M 16 |

18 |

2,2 |

| 60,3 |

- |

65 |

| 65 |

76,1 |

- |

185 |

81 |

16 |

145 |

5 |

4 |

M 16 |

18 |

2,62 |

| 80 |

88,9 |

- |

200 |

94 |

18 |

160 |

5 |

8 |

M 16 |

18 |

3,32 |

| 100 |

- |

108 |

220 |

113 |

18 |

180 |

5 |

8 |

M 16 |

18 |

3,67 |

| 114,3 |

- |

119 |

| 125 |

- |

133 |

250 |

138 |

18 |

210 |

5 |

8 |

M 16 |

18 |

4,54 |

| 139,7 |

- |

145 |

| 150 |

- |

159 |

285 |

164 |

18 |

240 |

5 |

8 |

M 20 |

22 |

5,6 |

| 168,3 |

- |

173 |

| 200 |

219,1 |

- |

340 |

225 |

20 |

295 |

5 |

8 |

M 20 |

22 |

7,46 |

| 250 |

- |

267 |

395 |

273 |

22 |

350 |

5 |

12 |

M 20 |

22 |

10,3 |

| 273 |

- |

279 |

| 300 |

323,9 |

- |

445 |

329 |

26 |

400 |

5 |

12 |

M 20 |

22 |

14 |

| 350 |

355,6 |

- |

505 |

362 |

28 |

460 |

6 |

16 |

M 20 |

22 |

18,5 |

| - |

368 |

374 |

| 400 |

406,4 |

- |

565 |

413 |

32 |

515 |

6 |

16 |

M 24 |

26 |

25 |

| - |

419 |

426 |

| (450) |

457 |

- |

615 |

467 |

38 |

565 |

6 |

20 |

M 24 |

26 |

30,6 |

| 500 |

508 |

- |

670 |

517 |

38 |

620 |

6 |

20 |

M 24 |

26 |

37 |

| 600 |

610 |

- |

780 |

618 |

44 |

725 |

7 |

20 |

M 27 |

30 |

56,3 |

| 700 |

711 |

- |

895 |

721 |

50 |

840 |

7 |

24 |

M 27 |

30 |

80,4 |

| 800 |

813 |

- |

1015 |

824 |

56 |

950 |

7 |

24 |

M 30 |

33 |

113,2 |

NOTE:

1. Facing according to DIN 2526

Flat face:

Form A, Face without any requirements

Form B, Face Rz=160, machined (not smoother than 40µm)

Raised Face:

Form C, Face Rz=160, machined (not smoother than 40µm)

Form D, Face Rz=40, machined

Form E, Face Rz=16, machined

2. Tongue and groove according to DIN 2512

Form F, Tongue

Form N, Groove

3. Male and Female according to DIN 2513, DIN 2514

Form V13, V14, Male

Form R13, R16, Female

4. Chemfering for diaphragm-weld packings, PN64-PN400, according to DIN 2695

5. Facing for lens-shaped joints, PN64-PN400, according to DIN 2696

We've been manufacturing DIN FLANGE PN6-PN40 since 2002. Our operations are ISO 9001:2008 certified, and we can deliver a 20-foot container order in 3-4 weeks. Browse through our Product Showroom, and then send us your inquiries. Here, we always reply within 24 hours. For urgent requirement you can email to manager@hexionsteel.com

flange-type-pn6pn40-dinflanges |