Home / Products / Nickel Alloys / Incoloy 825 / ASTM B366 Incoloy 825 Weldolet

We manufacture a wide range of stainless steel, nickel alloy, copper alloy, inconel ,monel, hastelloy and other non-ferrous weldolets that is made using premium quality raw material. These weldolets are accompanied with hot dip galvanizing and electro polishing services for increasing their functional life. For meeting the demands of our quality conscious clients, we provide these weldolets along with mill test certificate as per EN 10204 / 3.1B.

ASTM B366 Incoloy 825 Weldolet

Specifications

| Standards |

Designation |

| ASTM |

B 366 |

| ASME |

SB 366 |

| UNS |

N08825 |

| Werkstoff Nr. |

2.4858 |

ASTM B366 Incoloy 825 Weldolet Inventory Stock at factory rate:-

Dimensions

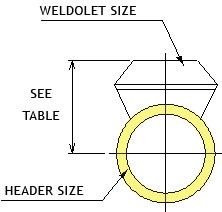

BN-DS-C12 Pipe fitting weldolet overall dimensions

The below standard gives overall dimensions for study purposes of general weldolets.

| HEADER |

PIPE WEIGHT |

WELDOLET SIZE |

| SIZE |

OR SCH. NR. |

2" |

3" |

4" |

6" |

8" |

10" |

12" |

14" |

16" |

18" |

20" |

24" |

| 2" |

STD-40

XS-80 |

70 |

|

|

|

|

|

|

|

|

|

|

|

|

XXS-160 |

87 |

|

|

|

|

|

|

|

|

|

|

|

| 3" |

STD-40

XS-80 |

84 |

91 |

|

|

|

|

|

|

|

|

|

|

|

XXS-160 |

101 |

119 |

|

|

|

|

|

|

|

|

|

|

| 4" |

STD-40

XS-80 |

97 |

103 |

111 |

|

|

|

|

|

|

|

|

|

|

XXS-160 |

114 |

132 |

144 |

|

|

|

|

|

|

|

|

|

|

STD-40 |

124 |

130 |

138 |

148 |

|

|

|

|

|

|

|

|

| 6" |

XS-80 |

124 |

130 |

138 |

165 |

|

|

|

|

|

|

|

|

|

XXS-160 |

141 |

159 |

171 |

192 |

|

|

|

|

|

|

|

|

|

STD-40 |

149 |

156 |

164 |

176 |

183 |

|

|

|

|

|

|

|

| 8" |

XS-80 |

149 |

156 |

164 |

191 |

197 |

|

|

|

|

|

|

|

|

XXS-160 |

167 |

184 |

197 |

218 |

224 |

|

|

|

|

|

|

|

|

STD-40 |

176 |

183 |

191 |

205 |

210 |

218 |

|

|

|

|

|

|

| 10" |

XS-80 |

176 |

183 |

191 |

218 |

238 |

235 |

|

|

|

|

|

|

|

XXS-160 |

194 |

211 |

224 |

245 |

251 |

265 |

|

|

|

|

|

|

|

STD |

202 |

208 |

216 |

228 |

255 |

245 |

251 |

|

|

|

|

|

| 12" |

XS |

202 |

208 |

216 |

243 |

264 |

267 |

265 |

|

|

|

|

|

|

XXS-160 |

219 |

237 |

249 |

270 |

276 |

291 |

324 |

|

|

|

|

|

| 14" |

STD |

218 |

224 |

232 |

245 |

251 |

259 |

267 |

270 |

|

|

|

|

|

XS |

218 |

224 |

231 |

239 |

279 |

270 |

278 |

286 |

|

|

|

|

| 16" |

STD |

243 |

249 |

257 |

270 |

276 |

284 |

292 |

295 |

300 |

|

|

|

|

XS |

243 |

249 |

257 |

284 |

305 |

293 |

303 |

306 |

319 |

|

|

|

| 18" |

STD |

268 |

275 |

283 |

295 |

302 |

310 |

318 |

321 |

325 |

335 |

|

|

|

XS |

268 |

275 |

283 |

310 |

330 |

321 |

329 |

332 |

338 |

352 |

|

|

| 20" |

STD |

294 |

300 |

308 |

321 |

327 |

335 |

343 |

346 |

351 |

356 |

376 |

|

|

XS |

294 |

300 |

308 |

335 |

356 |

346 |

354 |

557 |

364 |

370 |

386 |

|

| 24" |

STD |

345 |

351 |

359 |

372 |

378 |

386 |

394 |

397 |

402 |

406 |

411 |

446 |

|

XS |

345 |

351 |

359 |

386 |

406 |

397 |

405 |

408 |

414 |

421 |

429 |

449 |

NOTES:

- WHEN A WELDOLET WITH A LIGHTER WALL THICKNESS, OTHER THAN THOSE LISTED, IS REQUIRED, USE THE DIMENSION OF THE NEAREST HEAVIER WALL.

- EXAMPLE FOR ORDERING WELDOLETS.

SIZE DESCRIPTION MATERIAL

10 x 4 WELDOLET SCH. 40 C.S

(Header size X Weldolet size)

Chemical Composition

|

Incoloy 825 |

| Ni |

38.0 – 46.0 |

| Cr |

19.5 – 23.5 |

| Fe |

22.0 min |

| Mb |

2.5 – 3.5 |

| Ti |

0.6 – 1.2 |

| Cu |

1.5 – 3.0 |

| Mn |

1.0 max |

| C |

0.05 max |

| S |

0.03 max |

| Al |

0.2 max |

| Si |

0.5 max |

Mechanical & Physical Properties – Incoloy 825

| Density |

8.14 g/cm3 |

| Melting Point |

1400 °C (2550 °F) |

| Tensile Strength |

Psi – 80,000 , MPa – 550 |

| Yield Strength (0.2%Offset) |

Psi – 32,000 , MPa – 220 |

| Elongation |

30 % |

Main Export Market

- Eastern Europe

- North America

- Mid East/Africa

- Central/South America

- Asia

- Western Europe

- Australasia

- UAE

Sales Locations

U.A.E,

Oman,

Saudi Arabia,

Qatar,

Bahrain,

Egypt,

Turkey

Singapore,

Thailand,

Malaysia

Indonesia

Poland

Italy

Portugal

Spain

Brazil

Chile

Venezuela

Costa Rica

USA

Canada

Angola

Sri Lanka

Russia