→ PRODUCTS

We are industrial suppliers of ASME B16.9 180° Long Radius Elbow

We are industrial suppliers of ASME B16.9 180° Long Radius Elbow

|

|

Home / Products / Butt-Welding Fittings / ANSI/ASME B16.9 180° Long Radius Elbow

We are a leading professional manufacturer of Stainless Steel, Nickel Alloy, Copper Alloy, Carbon Steel, Alloy Steel Butt Weld Pipe Fittings according to ANSI/ASME B16.9 180° Long Radius Elbow Standard, DIN and JIS Standard.

ANSI/ASME B16.9 180° Long Radius Elbow

| Standards: |

ANSI - B 16.9

ASTM A403 - ASME SA403 - 'Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings'

API 590-605

ASME B16.9 - 'Factory-Made Wrought Buttwelding Fittings''

ASME B16.25 - 'Buttwelding Ends'

ASME B16.28 - 'Wrought Steel Buttwelding Short Radius Elbows and Returns'

MSS SP-43 - 'Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications' |

| Schedule: |

Sch 5 TO Sch XXS. |

| Sizes: |

Diameters - from 21,3 to 711 mm.

Wall Thickness - from 2 to 40 mm. |

| Materials: |

Monel, Nickel, Inconel, Hastalloy, Titanium, Tantalum, Stainless Steel, Alloy Steel, Carbon Steel, Cupro-Nickel 90/10 & 70/30

Stainless Steel ASME / ASTM SA / A403 SA / A 774 WP-S, WP-W, WP-WX, 304, 304L, 316, 316L, 304/304L, 316/316L, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Type: |

Butt Weld (BW) |

| Thickness: |

Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Dimension: |

ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

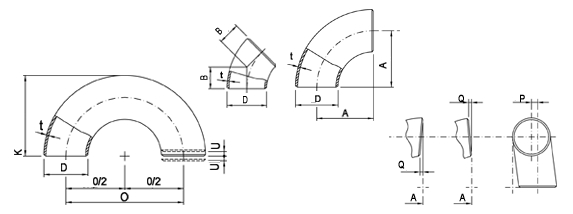

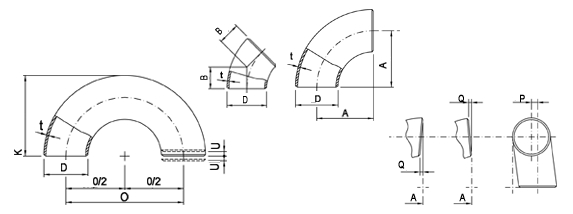

Dimensions

Nom.

Pipe

Size |

Pipe

Sched.

or No. |

Center-

to-Center

Dimen. |

Back-

to-

Face |

Outside

Dia. |

Inside

Dia. |

Wall

Thick. |

Approx.

Weight

(lb.) |

|

|

H |

J |

OD |

ID |

T |

|

| STANDARD WEIGHT |

|

|

|

|

|

| 1/2 |

40 |

3 |

1 7/8 |

0.840 |

0.622 |

0.109 |

0.3 |

| 3/4 |

40 |

2 1/2 |

1 11/16 |

1.050 |

0.824 |

0.113 |

0.3 |

| 1 |

40 |

3 |

2 3/16 |

1.315 |

1.049 |

0.133 |

0.7 |

| 1 1/4 |

40 |

3 3/4 |

2 3/4 |

1.660 |

1.380 |

0.140 |

1 |

| 1 1/2 |

40 |

4 1/2 |

3 1/4 |

1.900 |

1.610 |

0.145 |

1.5 |

| 2 |

40 |

6 |

4 3/16 |

2.375 |

2.067 |

0.154 |

3 |

| 2 1/2 |

40 |

7 1/2 |

5 3/16 |

2.875 |

2.469 |

0.203 |

6 |

| 3 |

40 |

9 |

6 1/4 |

3.500 |

3.068 |

0.216 |

9 |

| 3 1/2 |

40 |

10 1/2 |

7 1/4 |

4.000 |

3.548 |

0.226 |

12 |

| 4 |

40 |

12 |

8 1/4 |

4.500 |

4.026 |

0.237 |

17 |

| 5 |

40 |

15 |

10 5/16 |

5.563 |

5.047 |

0.258 |

28 |

| 6 |

40 |

18 |

12 5/16 |

6.625 |

6.065 |

0.280 |

46 |

| 8 |

40 |

24 |

16 5/16 |

8.625 |

7.981 |

0.322 |

90 |

| 10 |

40 |

30 |

20 3/8 |

10.750 |

10.020 |

0.365 |

156 |

| 12 |

- |

36 |

24 3/8 |

12.750 |

12.000 |

0.375 |

236 |

| 14 |

30 |

42 |

28 |

14.000 |

13.250 |

0.375 |

294 |

| 16 |

30 |

48 |

32 |

16.000 |

15.250 |

0.375 |

404 |

| 18 |

- |

54 |

36 |

18.000 |

17.250 |

0.375 |

512 |

| 20 |

20 |

60 |

40 |

20.000 |

19.250 |

0.375 |

617 |

| 24 |

20 |

72 |

48 |

24.000 |

23.250 |

0.375 |

886 |

| EXTRA STRONG |

|

|

|

|

|

|

| 1/2 |

80 |

3 |

1 7/8 |

0.840 |

0.546 |

0.147 |

0.5 |

| 3/4 |

80 |

2 1/2 |

1 11/16 |

1.050 |

0.742 |

0.154 |

0.5 |

| 1 |

80 |

3 |

2 3/16 |

1.315 |

0.957 |

0.179 |

1 |

| 1 1/4 |

80 |

3 3/4 |

2 3/4 |

1.660 |

1.278 |

0.191 |

1.5 |

| 1 1/2 |

80 |

4 1/2 |

3 1/4 |

1.900 |

1.500 |

0.200 |

2 |

| 2 |

80 |

6 |

4 3/16 |

2.375 |

1.939 |

0.218 |

4 |

| 2 1/2 |

80 |

7 1/2 |

5 3/16 |

2.875 |

2.323 |

0.276 |

7.5 |

| 3 |

80 |

9 |

6 1/4 |

3.500 |

2.900 |

0.300 |

12 |

| 3 1/2 |

80 |

10 1/2 |

7 1/4 |

4.000 |

3.364 |

0.318 |

17 |

| 4 |

80 |

12 |

8 1/4 |

4.500 |

3.826 |

0.337 |

23 |

| 5 |

80 |

15 |

10 5/16 |

5.563 |

4.813 |

0.375 |

40 |

| 6 |

80 |

18 |

12 5/16 |

6.625 |

5.761 |

0.432 |

67 |

| 8 |

80 |

24 |

16 5/16 |

8.625 |

7.625 |

0.500 |

138 |

| 10 |

60 |

30 |

20 3/8 |

10.750 |

9.750 |

0.500 |

215 |

| 12 |

- |

36 |

24 3/8 |

12.750 |

11.750 |

0.500 |

300 |

| 14 |

- |

42 |

28 |

14.000 |

13.000 |

0.500 |

376 |

| 16 |

40 |

48 |

32 |

16.000 |

15.000 |

0.500 |

524 |

| 18 |

- |

54 |

36 |

18.000 |

17.000 |

0.500 |

676 |

| 20 |

30 |

60 |

40 |

20.000 |

19.000 |

0.500 |

824 |

| 24 |

- |

72 |

48 |

24.000 |

20.000 |

0.500 |

1183 |

ELBOWS - Ansi 16.9 tolerances

| DIMENSIONAL TOLERANCES - ELBOWS |

| For all fittings |

Elbows 90/45 deg |

180° Returns |

| Nominal Pipe Size (NPS) |

Outside Ø

at Bevel |

Inside Ø

at End |

Wall Thickness

t / t1 |

Center to End Dim. A-B-C-M |

Center to Center Dim.

O |

Back to Face Dim.

K |

Align- ment of Ends

U |

| 1/2 a 2 1/2 |

1 |

0,8 |

Not |

2 |

7 |

7 |

1 |

| 3 a 3 1/2 |

1 |

1,6 |

less |

2 |

7 |

7 |

1 |

| 4 |

+2 -1 |

1,6 |

than |

2 |

7 |

7 |

1 |

| 5 a 6 |

+3 -1 |

1,6 |

87,50% |

2 |

7 |

7 |

1 |

| 8 |

2 |

1,6 |

of nominal |

2 |

7 |

7 |

1 |

| 10 |

+4 -3 |

3,2 |

tickness |

2 |

7 |

7 |

2 |

| 12 a 18 |

+4 -3 |

3,2 |

|

3 |

10 |

7 |

2 |

| 20 a 24 |

+6 -5 |

4,8 |

|

3 |

10 |

7 |

2 |

| 26 a 30 |

+7 -5 |

4,8 |

|

3 |

..... |

..... |

..... |

| 32 a 48 |

+7 -5 |

4,8 |

|

5 |

..... |

..... |

..... |

| Angularity Tolerances |

| ND |

Max off angle |

Max off plane |

| Q |

P |

| 1/2 a 4 |

1 |

2 |

| 5 a 8 |

2 |

4 |

| 10 a 12 |

3 |

5 |

| 14 a 16 |

3 |

7 |

| 18 a 24 |

4 |

10 |

| 26 a 30 |

5 |

10 |

| 32 a 42 |

5 |

13 |

| 44 a 48 |

5 |

20 |

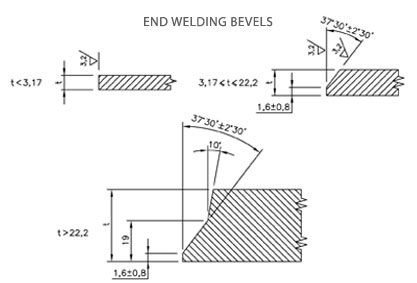

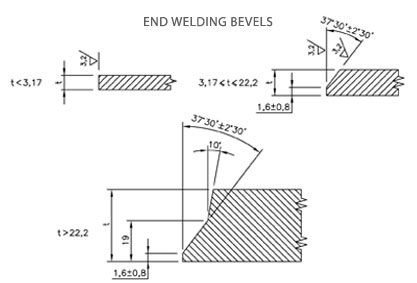

ELBOWS - End welding bevels

Main Export Market

- Eastern Europe

- North America

- Mid East/Africa

- Central/South America

- Asia

- Western Europe

- Australasia

- UAE

Sales Locations

U.A.E,

Oman,

Saudi Arabia,

Qatar,

Bahrain,

Egypt,

Turkey

Singapore,

Thailand,

Malaysia

Indonesia

Poland

Italy

Portugal

Spain

Brazil

Chile

Venezuela

Costa Rica

USA

Canada

Angola

Sri Lanka

Russia

|